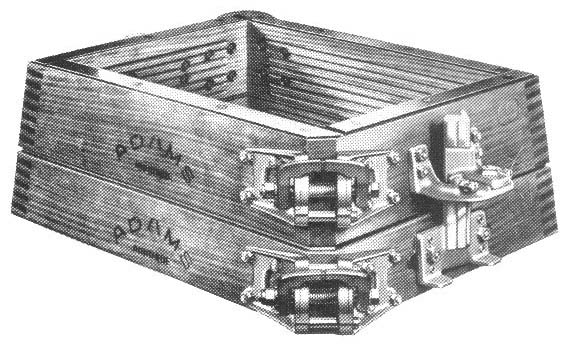

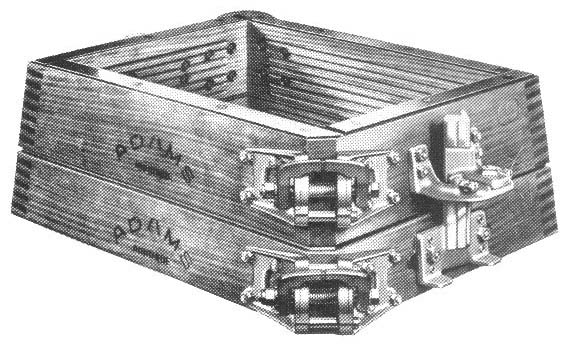

| Made with the finest cherry wood, these flasks are custom-built to maintain their shape, withstand shock and resist moisture. Each board is carefully hand selected, then air dried for two years to insure its strength. Ends and sides are individually cut, mated, dovetailed, hot glued, machine locked, and mounted with steel wear strips for lasting rigidity and squareness. Accurate alignment of cope and drag is assured through expert craftsmanship. |

| Available with a wide selection of pins and ears to meet your existing pattern requirements. Operating mechanisms are ruggedly built, simple in operation. When using synthetic sands or higher squeeze pressures, the "Easy-Off" Flask operates with a spreading motion for a more rapid removal. Sections finished 1 1/8" on all standard size flasks, 1 1/4" and heavier on flasks of larger perimeter and depths. |

|

STANDARD SPECIFICATIONS

|

|

Standard Cherry "Easy-Off" Flasks are manufactured

according to the following minimum and maximum sizes: |

|

"EASY-OFF" OPERATING MECHANISM

|

| The #900 corner mechanism incorporates aluminum body castings which are bolted directly onto the flask sections. Opened and closed by an integral operating handle. Handle can be mounted to lock up (standard) or down. Corner mechanisms can be mounted for right hand (standard) or left hand operation. Depth determined by the cope or drag depth on the flask. |

|

PINS AND TRUNNIONS

|

| Hines offers a wide range of flask trimmings to completely customize your foundry equipment. With our selection of pins and ears, you can match any existing arrangement. Adams Style hardware can interchange with your pattern guides and match your pin centers exactly Select from Wide "V", Single Round or Double Round with Adjustable Ears, Single Round or Single Round and Hexagon with Round and Elongated Bushings. Additional options on "Easy-Off" Flasks include Aluminum Roll-Over Trunnions, Automated Matchplate Molding Machine Trunnions and Heavy-Duty Roll-Over Trunnions. Upsets available to fit either copes or drags. |

| Brackets are mounted with #10 1 " flat head wood screws. Leg and bracket body are assembled with two 1/4" 20 thread x 3/8" round head machine screws with 1/4" internal washers. Available in two sizes: |

|

|

|

|

#800-1 Small Leg for upsets up to 2"

deep

|

#800-2 Large Leg for upsets 2"

and over

|

#800-3 Upset Bracket Body for use with

#800-1 or #800-2

|