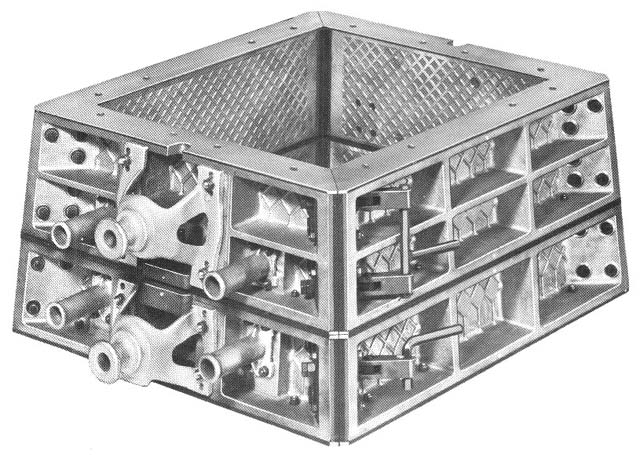

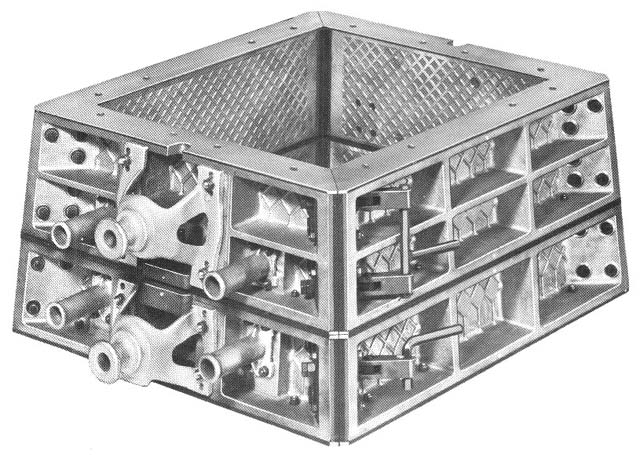

| This rugged "POP-OFF" flask is designed especially for use with the new high pressure molding machines utilizing large diameter squeeze pistons and simultaneous jolt, ram, or rap squeeze. The heavy 3" wide flanges and ¼" welded steel facing resist deflection. The rugged corner design and the new "POP-OFF" corner plate material assure smooth long-lasting operation. This rugged Texas flask is built of precision machined components for easy replacement of all parts. |

| If you are using or contemplating the use of this type of equipment, this is the only flask that will do the job consistently year in and year out. IT'S ENGINEERED TO DO THE JOB. DON'T SETTLE FOR LESS. GO TEXAS. |

|

STANDARD SPECIFICATIONS

|

|

Material: Aluminum Lengths: 20" to 60" (inside of parting) Widths: 20" to 60" (inside of parting) Depths: Cope: 6", 8", 10", 12", 14", 16" 8" Drag: 6", 8", 10", 12", 14", 16" Taper: 4° only Flanges: 3" wide Lugs: Bolt on Facings: ¼" cold rolled steel on all flanges standard "POP-OFF" Mechanism: EP-150 Clevis mechanisms as follows: Section Depth 6" One mechanism each corner 8" Two mechanisms each corner 10" Two mechanisms each corner 12" Two mechanisms each corner 14" Three mechanisms each corner 16" Three mechanisms each corner Handles: Standard equipment Trunnions: Standard equipment Pins and Bushings: All standard single pin and bushing arrangements. Minimum Pin Centers: Flask length plus 3 ¾" |