|

STANDARD SPECIFICATIONS

|

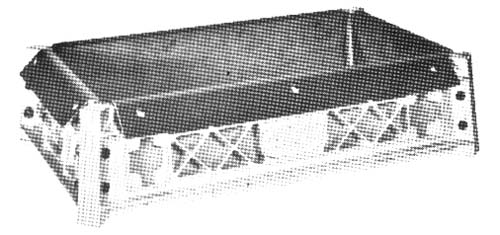

| Material: Cast Iron or

Cast Aluminum with "FOUNDRITE" Lining Jacket Lengths: Measured at parting line of mold 10" to 48" Jacket Widths: Measured at parting line of mold 10" to 48" Jacket Taper: Standard tapers are 3°, 4°, and 5° Jacket Depths: Standard depths are 4 ½", 6", 8", and 10" Other sizes and depths available. Prices on request. Optional Equipment: One or two man handles as specified. Tubing reinforcements for jackets over 36" in length, and steel spill shields are available at extra cost. |

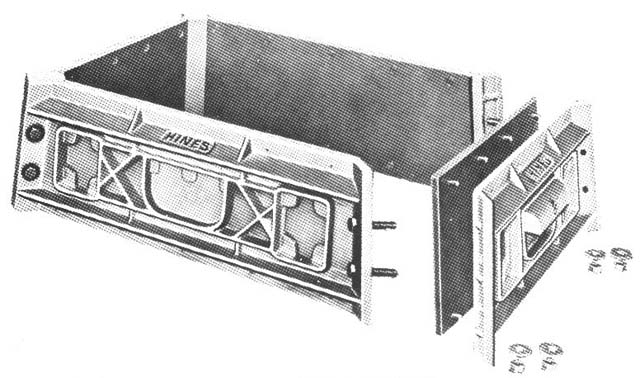

SPILL SHEILD

|

Hines "FOUNDRITE" non asbestos lined

jackets with spill shields protect jacket sides from metal spillage

during pouring. These spill shields are available with any Hines jacket.

|