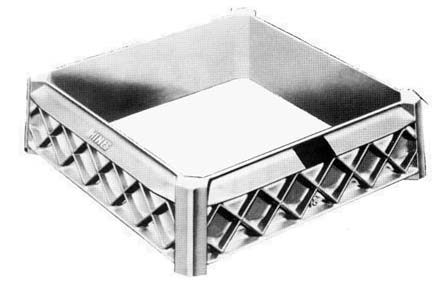

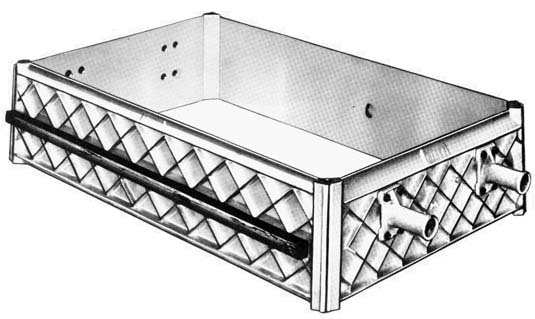

| Hines "SOLID" Cast Aluminum and Cast Iron Jackets are fixture built with reinforcing ribs uniformly distributed and cast into the jackets. Special ribbing provides additional strength and protection against warpage. Spill shields and reinforcing tubing are available at extra cost. |

Hines Cast Aluminum Jacket

Hines Cast Iron Jacket with reinforcing tubing

|

STANDARD SPECIFICATIONS

|

| Material: Cast Iron or

Cast Aluminum Jacket Lengths: Measured at parting line of mold 10" to 36" Jacket Widths: Measured at parting line of mold 10" to 36" Jacket Taper: Standard tapers are 3°, 4°', and 5° Jacket Depths: Standard depths are 4½", 6", 8", and 10" Special sizes and depths customized to your specifications are available. Optional Equipment: One or two man handles as specified. Tubing reinforcements for jackets over 36" in length, and steel spill shields are available at extra cost. |

![]()

|

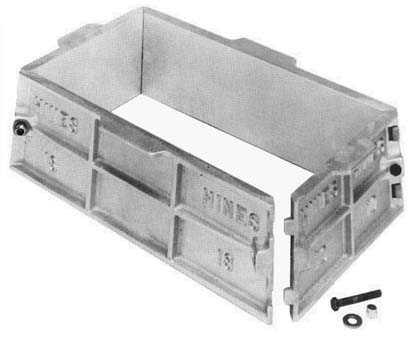

"HINES-ALIGN" JACKETS

|

| An ingenious pivot-pin arrangement at its four corners gives "Hines-Align" jackets unique flexibility to fit any Taper Mold. "Hines-Align" assumes the exact mold shape adjusting to its taper. The fit on the mold in relationship to the parting line can be changed by the loosening or the tightening of the corner bolts. Side or end replacements can be made in minutes. |

|

STANDARD SPECIFICATIONS

|

| Material: Cast Aluminum Jacket Lengths: Measured at parting line of mold 10" to 24" Jacket Widths: Measured at parting line of mold 10" to 24" Jacket Depth: Standard depth 6" Jackets are shipped broken down with complete hardware for easy assembly. |