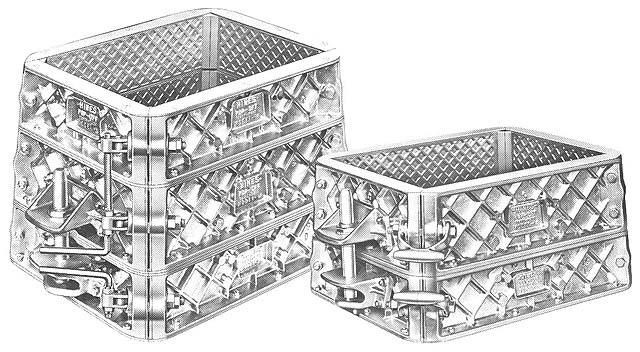

Material: Aluminum or Magnesium

Lengths: every inch, 12" to 24" (inside of parting)

Widths: every inch, 10" to 24" (inside of parting)

Depths: Cope: every ½ inch, 3" to 7"

Drag:

every ½ inch, 3" to 7"

Other flask depths obtained by adding Upset Frames to cope and/or drag.

Taper: 3°, 4° or 5° Flanges:

1¼" wide

Facings: Steel, top of cope and bottom of drag.

"Pop-Off " Levers: No. 70 levers are standard equipment

and

move up, or together, to locked position. Clevis assemblies

extra.

Handles: Available when specified.

Trunnions: For use on "Rota-Lift"® and Rol-N-Rap®

machines, at extra cost.

|

Double round pins and guides-flask

length plus 2¾"

Single round or hex pins, guides or bushings-flask length plus 3¾"

"V" pins and guides (apex to apex)-flask length plus 4¼"

All pins, guides and bushings are HINES STANDARDS only

Machined pads for customers to attach their own pins.

|