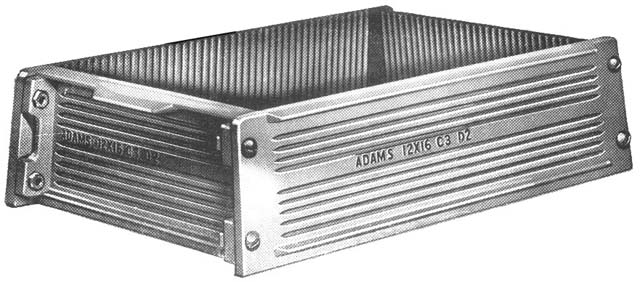

| All sections are vertically grooved inside and ribreinforced outside. |

| Lifting handles are incorporated in the well-balanced end sections of all small sizes. Special handles on large sizes. |

| Minimum weight, maximum strength and rigidity are assured. |

| Part replacement in your own plant is quick and simple. The sections, sides or ends you order arrive jig drilled and milled. |

| Let us offer recommendations to meet your particular requirements. |

|

STANDARD SPECIFICATIONS

|

| Material: Cast Iron or

Cast Aluminum Jacket Lengths: Measured at parting line of mold 12" to 48" Jacket Widths: Measured at parting line of mold 10" to 36" Jacket Taper: Standard tapers are 3°, 4°, and 5° Jacket Depths: Standard depths are 5", 6", 8", and 10" Special sizes and depths customized to your specifications are available. Optional Equipment: One or two man handles as specified. |